Machine Description:

The machine adopts motion control system so it can run high speed

The machine adopts motion control system so it can run high speed

Adopt the servo motor to rotate the bottle holder to adjust the screw and adjust the size of the cup holder. When changing the bottle type, the machine uses an one-button switching mode, so that the operation is more convenient and time-saving.

When the bottle enters the bottle washing station, the servo motor rotates to drive the bottle to 180 degrees, while blowing and inhaling, and rotating 180 degrees after the bottle is finished, so that the inside of the bottle is clean before filling

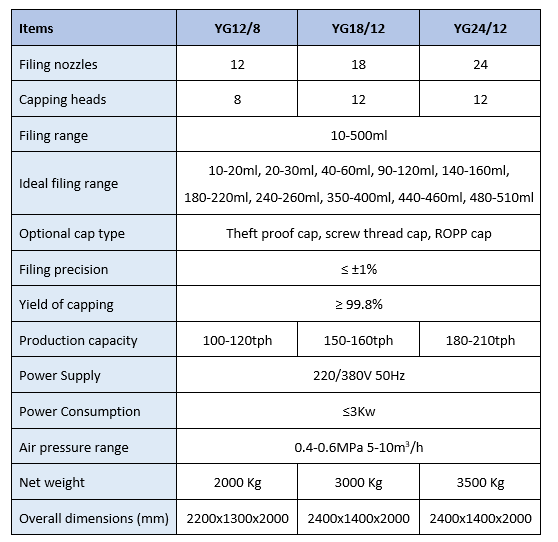

Adopting servo motor to drive the machine. Adjust the filling volume automatically by changing the parameters from the HMI screen to make the operation more convenient. The filling nozzle is driven by a servo motor, which can be raised while filling to prevent the material from bubbling and spilling out of the bottle.

the vibration bowl arranges the plug, and the track is equipped with the plug detection sensor. When the plug is full on track, the vibration disc stops working and reduces noise. The servo motor drives the plug to rotate the internal plug to improve the speed of internal plug removal. When the inner plug is used, the cylinder head is positioned by cylinder to improve the success rate of plugging. The machine gives alarm when no plug will be detected by the sensor.

Manually rotate the lid to the bottle opening then the servo motor drives the capping jaw to rotate the cap, and thus the torque can be directly adjusted on the touch screen.

the mechanical arms grabs the bottle, detaches from the bottle holder, and puts it into the conveyor to save labour working and improving efficiency.